A growing number of architects and designers are turning to new technology to bring concepts to life, and one of the biggest shifts has come from how a model builder now approaches visualisation. Instead of relying solely on manual crafting, professionals can merge craftsmanship with innovation to speed up early-stage design work. This change has allowed more detailed representations to emerge in the early planning phase, helping teams communicate ideas clearly.

Traditional scale models once required hours of cutting, shaping, and refining by hand, but the introduction of 3d printing into the workflow has changed the pace completely. Today, firms can test proportions, experiment with layouts, and refine structural details before committing to final drawings. This evolution has made it easier for a model builder to streamline tricky or repetitive tasks while still maintaining a high level of accuracy and artistic intention.

Creating an architectural model was once a slow, intricate process, often limited by the materials available. With digital tools and advanced fabrication methods, designers can now replicate curves, interiors, textures, and complex patterns in ways that were previously impossible. And as 3d printing continues to advance, it’s opening new creative and practical possibilities for both small and large projects.

Why Technology Has Transformed Physical Design Models

The arrival of additive manufacturing has made precise, reliable replicas far more attainable. Instead of shaping foam, cardboard, or wood by hand, teams can translate digital drawings directly into scaled components. This gives architects the opportunity to see how a concept will behave in real-world space long before construction begins.

Another major benefit is the ability to experiment. When ideas can be printed quickly and adjusted with ease, it encourages designers to try more daring structural elements. Complex rooflines, organic curves, and multi-layered façades become easier to showcase without excessive manual labour, making early visualisation far more dynamic.

In many firms, these tools also help reduce errors. By printing individual sections separately, problems can be spotted early, allowing professionals to fix proportions, alignment, or spacing before committing to full presentations.

How 3D Printing Improves Accuracy and Detail

One of the biggest strengths of additive fabrication is its ability to recreate minute details. Layer-by-layer construction allows tiny elements—such as window frames, decorative trims, stair rails, and façade textures—to appear with remarkable precision. These details were once extremely time-consuming to produce by hand.

To achieve this, many design teams break down a structure into components so the final architectural model shows depth and realism. The process also helps when demonstrating spatial flow, allowing clients to better understand movement between rooms and levels.

In addition, 3d printing enables the use of different materials depending on the effect required. Some sections may be printed with rigid plastics for stability, while more flexible filaments can be used for unusual shapes or unique design features. This flexibility makes each model more expressive and adaptable.

Steps a Model Maker Might Follow

The workflow can vary slightly between firms, but the general stages remain consistent. Many teams follow a structure similar to this:

-

Translate sketches or CAD drawings into a printable digital format.

-

Break the project into smaller parts suitable for fabrication.

-

Print each section using chosen materials and settings.

-

Assemble, refine, and paint the finished components.

-

Add landscape, lighting, or surrounding structures if required.

This process gives both architects and clients a tangible representation of the future build, often leading to faster approvals and more confident decision-making.

Benefits for Client Presentations and Approvals

Physical models remain a powerful communication tool, especially when proposals need to be presented to stakeholders who may not interpret floor plans easily. When the structure is displayed in three dimensions, discussions become clearer and more engaging.

Clients can interact with the materials, get a sense of scale, and visualise how different volumes connect. This often leads to more productive feedback sessions, and because alterations can be implemented quickly, revisions no longer stall the project timeline.

Moreover, 3d printing helps firms create multiple display versions for open days, exhibitions, or investment pitches without significantly increasing production costs.

Sustainability and Material Efficiency

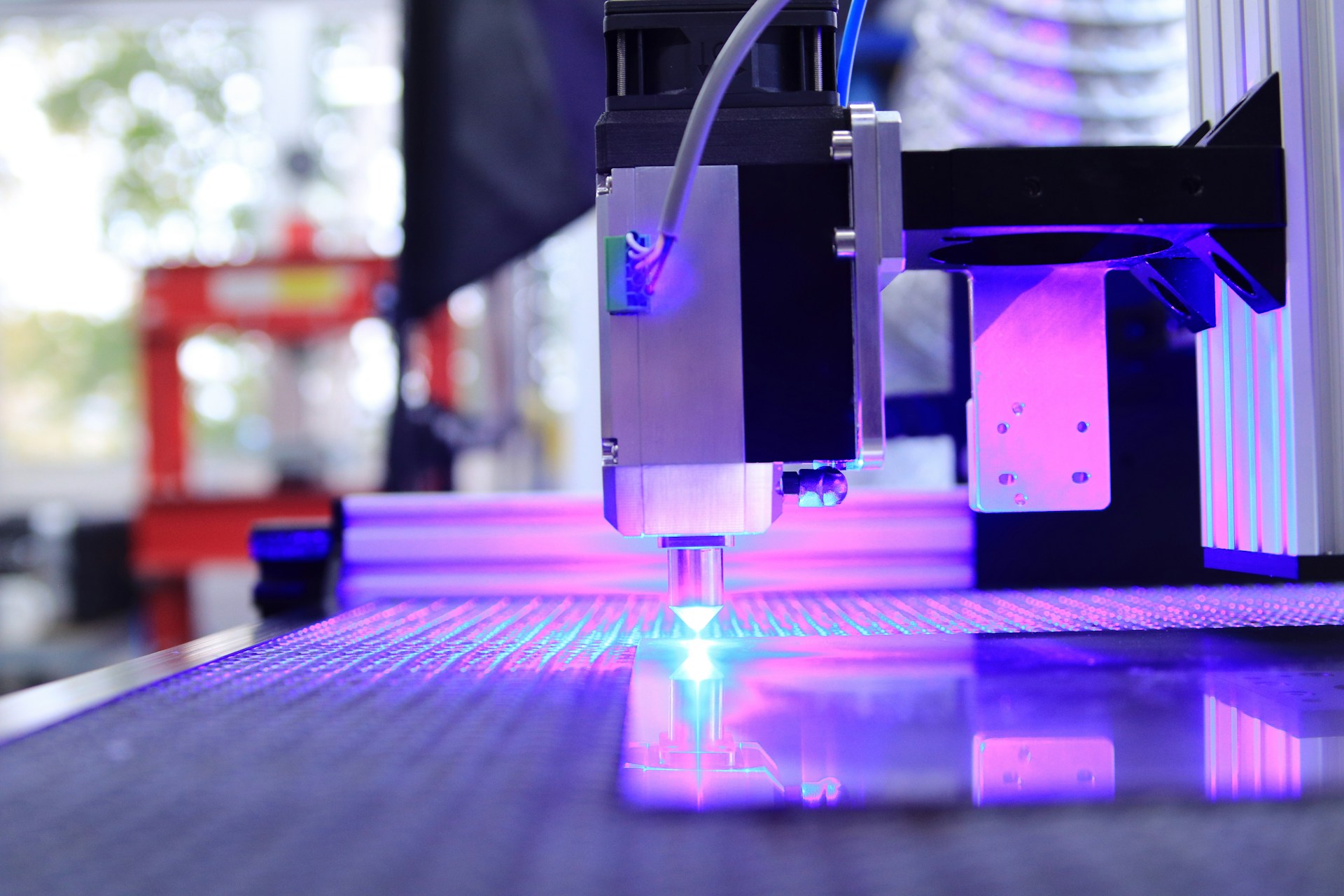

The ability to print only what is needed dramatically reduces waste. Laser cutting and hand-shaping often produce offcuts that cannot be reused, but additive processes generate minimal scrap. Environmentally friendly filament options are also becoming more common, allowing firms to reduce ecological impact.

This efficiency is especially useful when producing large or repeated architectural elements. If a model requires numerous identical pieces, each one can be printed consistently without added labour.

The Future of Scaled Architectural Representations

As technology evolves, we can expect even greater realism. Multi-material printers, colour-integrated fabrication, and faster production methods are already entering the industry. These improvements will make the architectural model even more integral to planning, marketing, and problem-solving.

What was once seen as a supplementary tool is now a critical part of the design process. By merging digital innovation with traditional craftsmanship, professionals are finding new ways to express creativity while enhancing accuracy and efficiency.